Project Neon

Las Vegas, NV

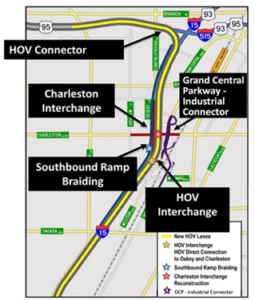

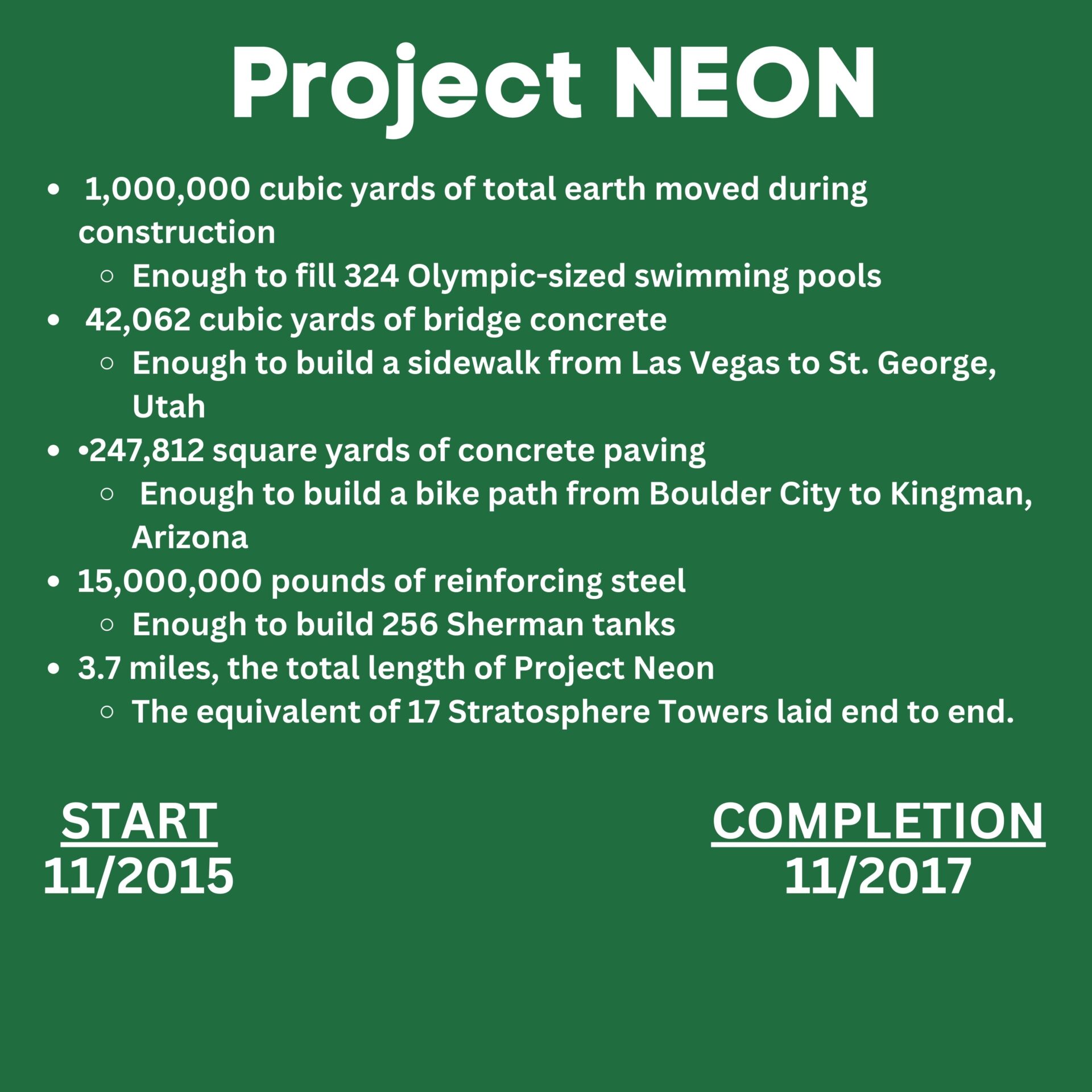

Project NEON was the largest public works project in Nevada history. Project NEON widened 3.7 miles of Interstate 15 between Sahara Avenue and the “Spaghetti Bowl” interchange in downtown Las Vegas. In 2016 it was the busiest stretch of highway in Nevada with 300,000 vehicles daily, or one-tenth of the state population, seeing 25,000 lane changes an hour. Traffic through the corridor is expected to double by 2035.

GES worked directly for the Atkins/Kiewit Design build team during the pursuit of this Design-Build project. This included the review of the RFP draft, the final RFP submittal, and all relevant geotechnical reference informational documents (RID’s). GES also evaluated the RID documents to establish a recommended drilled shaft load testing program and to identify additional geotechnical borings needed for final design of the project.

GES provided multiple geotechnical services for Project NEON including field explorations, drilling program for the entire project alignment, laboratory testing, engineering analysis and report preparation. Engineering analysis included Load and Resistance Factor Design (LRFD) analyses for 11 of the bridges, settlement estimations for embankments, bridge foundations, box culverts, and retaining walls, calculations for axial side and base resistance of drilled shaft foundations, lateral load resistance of drilled shaft foundations, external stability of mechanically-stabilized earth retaining structures, review of local street pavement designs, lateral earth pressure parameters for cast-in-place cantilever retaining walls, and the development of Alternative Technical Concepts (ATC’s) related to geotechnical design and construction issues.

To help establish drilled shaft foundations designs, five axial load tests were performed at locations along the project corridor. Load testing confirmed that the resistance to loads developed in the test shafts exceeded what the AASHTO default design equations provide.

GES’ sister company, Eagle Drilling, performed multiple services at the Project NEON site including:

- Use of an airknife to investigate the underground utilities in 82 boring locations up to 5 feet or refusal

- Hollow stem augers to drill 48 geotechnical borings. Boring depths ranged from 10 feet to 60 feet for a total depth of 1,735 feet Backfill with CLSM and surface complete with asphalt cold patch or concrete

Mud rotary drilling to drill 34 geotechnical borings ranging in depth from 70 feet to 100 feet for a total of 3,300 feet. Samples were taken at 2 feet, 5 feet, and every 5 feet thereafter for Auger and Mud drilling - Backfill mud rotary borings with bentonite grout and surface complete with concrete

In addition, GES prepared a Hazardous Materials Management Plan (HMMP) directly for Kiewit Infrastructure Engineers for project.

GES also provided construction support services and Hazardous Materials Management Support Services in support of construction activities for the duration of Project Neon Design Build.