As northern and southern Nevada become shipping centers, moving goods east from California ports, the number of large, even 1,000,000 square feet warehouses are becoming more common. These mega-buildings can be extremely tall with forty and even fifty feet of shelfing stocked by airjack operators and robots. At just forty feet high, a thousand-pound pallet can swing wildly on a bumpy floor. Therefore, floor flatness is becoming increasingly important.

It wasn’t that long ago when floor flatness was measured with a ten-foot straight edge on a finished floor. A foundation was deemed “flat” if the variation was less than 1/8th of an inch. But the method proved to be unreliable as no two people would get the same measurements.

When high stacking became mainstream in the 1970s flatness became more important. A pallet of copy paper weighs 1,840 pounds. Imagine the sway if one wheel of an airjack rolled over a quarter inch bump. The result was often damaged goods, broken equipment, and safety hazards.

In the 1980s the American Concrete Institute formalized the F-number system, providing a uniform method to measure floor flatness. Floors were then measured by flatness Ff and levelness Fl (ASTM E1155).

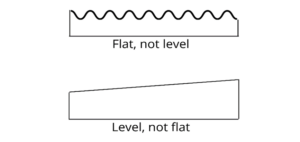

It’s possible for a floor to be flat, but not level, or level, but not flat.

F-numbers are created by taking 34 measurements for each 1,000 square feet of a concrete slab. The gathered data is then entered into a mathematical formula to derive the overall F-numbers. When using modern equipment, its very likely that two people will come up with very similar F-numbers. This is a striking departure from the straightedge method.

Floor flatness that as once measured with a ¼ inch defect across ten feet is now Ff25, with larger Ff numbers equating to even flatter floors.

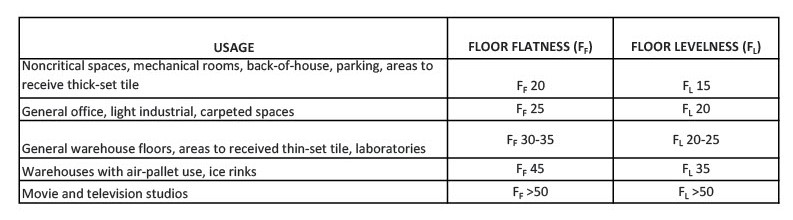

Architects are often asked how flat concrete floors should be for their projects. The answer could vary by project, but the American Concrete Institute suggests the following F values are acceptable based on the use listed.

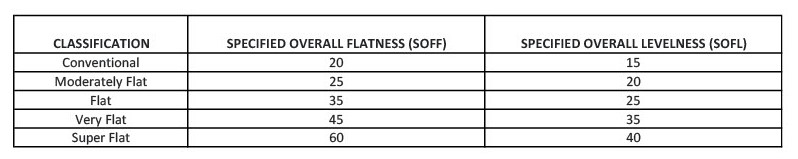

To meet specific flatness classifications a slightly different set of measurements must be met.

Floor, as certified by the American Society for Testing and Materials (ASTM), is just one of the third-party construction inspection services we provide to our clients. It’s a service we anticipate to grow in need as more industrial space becomes available on the edges of town.